|

》ISO 9002Certified by IAF/HLA (1998.10) |

》ISO14001CertifiedbyXGQC2007.052025.04 |

|

|

|

|

》IATF16949CertifiedbyDNV2016.012026.12 |

》ISO45001CertifiedbyXGQC2014.102026.08 |

|

|

|

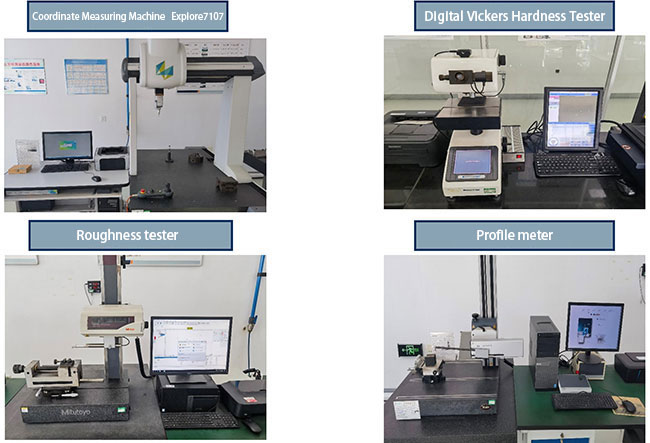

Testing Capabilities

JHEECO's precision testing laboratory is equipped with 20 major testing devices, including the Hickson coordinate measuring machine.Japanese Shimadzu Vacuum Spectrum Analyzer, Gear Measurement Center, OGP Optical Measuring Instrument, Japanese Shimadzu Surface Roughness Tester, German Mahr Contour Measuring Instrument, Magnetic Property Testing Device from the National Institute of Metrology of China, and other advanced domestic and international testing equipment.

JHEECO can conduct tests on geometric dimensions and shape tolerances, metal material analysis, tensile strength tests, magnetic testing, and metallographic analysis within the company, meeting the quality control of existing products and customer requirements.